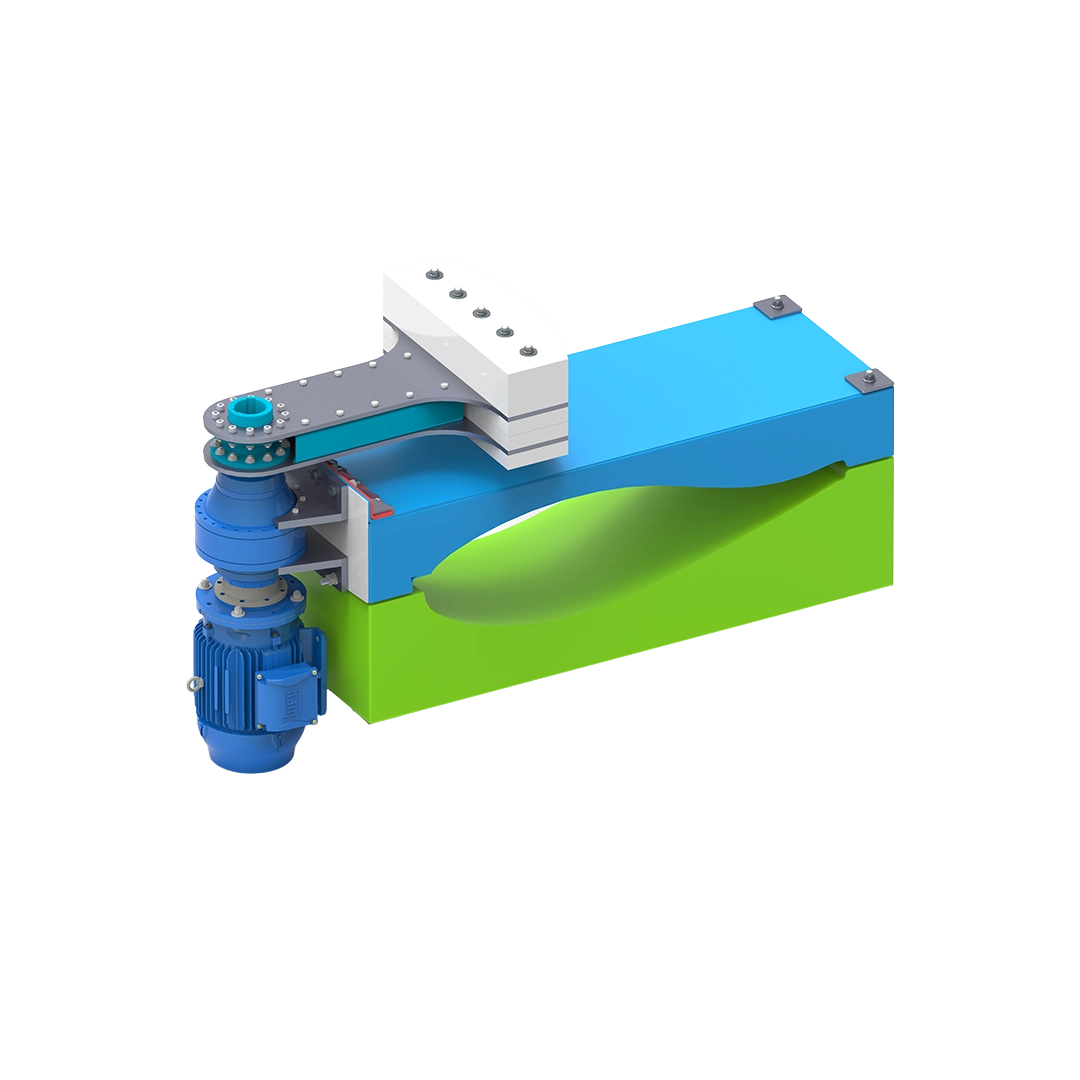

MAINTENANCE AND REPAIRS

Ensure the performance and durability of your wind turbines. We offer specialized solutions to keep your turbines operating at full efficiency — from detailed structural inspections to leading edge protection (LEP) application and development of custom repair projects for any need.

Our services include:

• Advanced Structural Inspection: We detect issues before they affect production.

• LEP Application: We protect against erosion and optimize aerodynamics.

• Custom Repairs: Precise engineering solutions to fully restore blade integrity.

Protect your investment and maximize energy generation.