Insertos soltos são um problema recorrente em algumas das pás mais utilizadas no mercado, podendo levar a falhas catastróficas se ultrapassarem um limite crítico, exigindo a interrupção da geração de energia. Esse problema geralmente ocorre devido à fixação inadequada das buchas de aço à estrutura de fibra de vidro, decorrente de falhas no controle de qualidade, defeitos de fabricação ou concentrações de tensões não detectadas na fase de projeto.

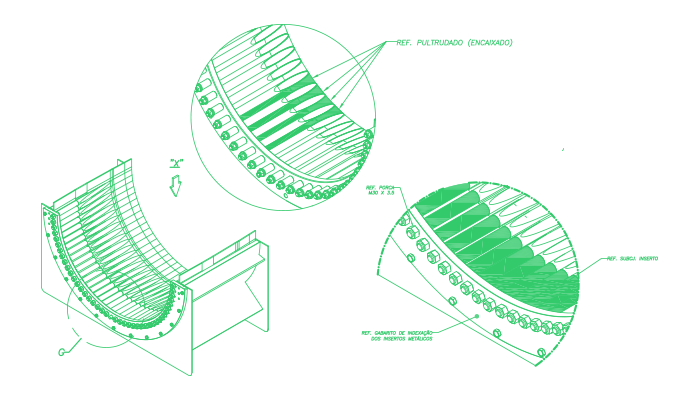

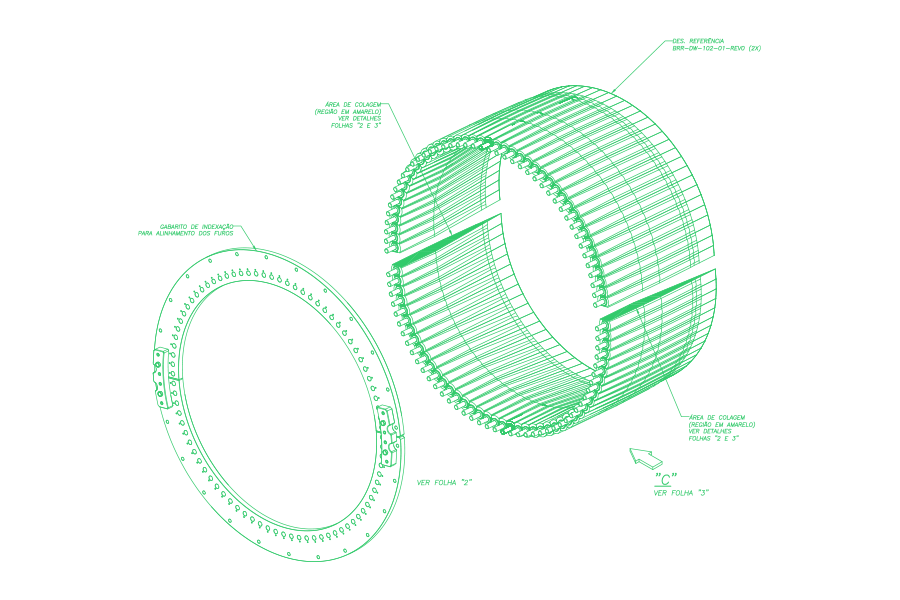

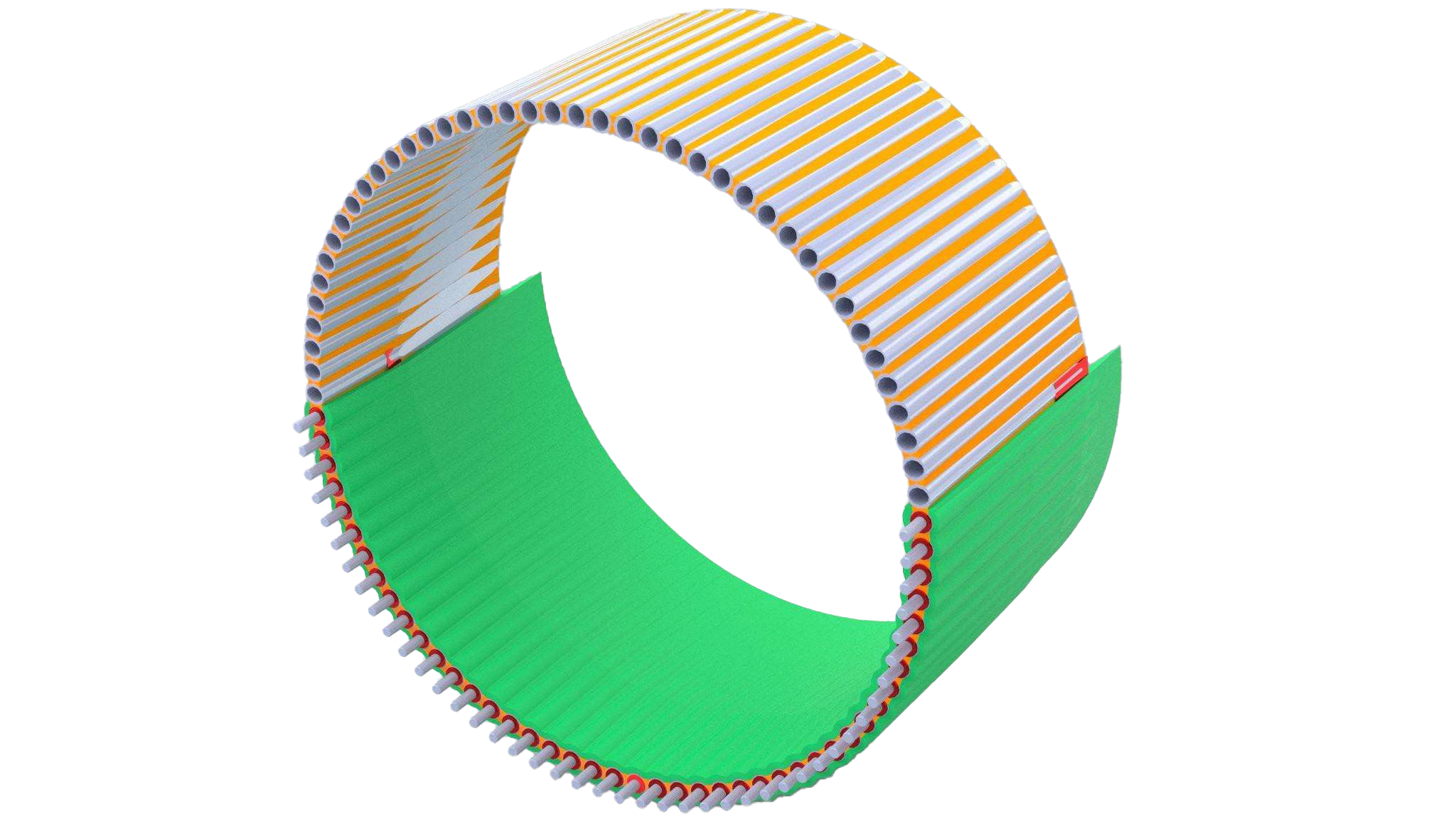

Nossa solução substitui a raiz da pá danificada por um novo componente certificado, com design otimizado e maior robustez estrutural.

Esse novo projeto corrige falhas de fabricação e garante compatibilidade total com o restante da pá e da turbina.

Loose inserts are a recurring issue in some of the most used blades in the market, potentially leading to catastrophic failures if they exceed a critical limit, requiring the interruption of power generation. This problem generates high costs and unexpected losses. The bushings fit into the fiber structure of the root and loosen due to manufacturing or quality defects, dimensional issues, or undetected problems during the design phase.

The blade composition is obtained through sample particle analysis, external geometry captured via 3D scanning of operational state, and internal structures measured from SCADA data and historical records.

Dynamic wind turbine models analyze blade behavior under various load conditions, in accordance with IEC 61400-1. Finite Element Analysis (FEA) examines stresses, deformations, and potential failure points, ensuring the new root withstands extreme operating conditions with defined safety margins and technical and manufacturing quality requirements.

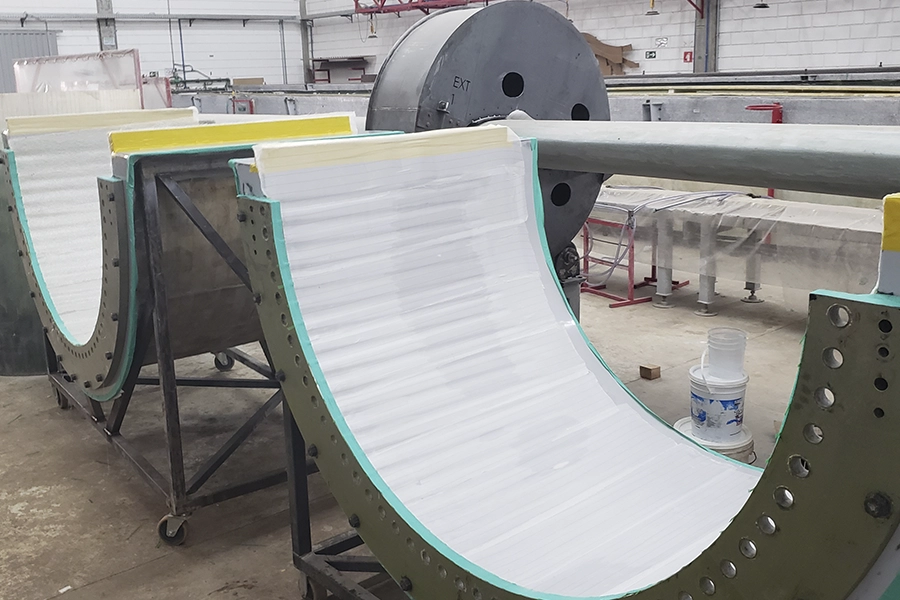

The new root is manufactured under strict quality controls, ensuring compliance with specifications and standards. All processes are tested on subcomponents to validate their resistance and assembly on the blade. The manufactured roots undergo laboratory testing, simulating extreme operating conditions to guarantee durability and performance. The projected minimum service life is 20 years, including a safety margin.

The new roots are manufactured in our facilities and transported to the wind farm. On-site, the first step is removing the damaged root and preparing the blade to receive the new one. Installation is carried out by specialized technicians following strict safety protocols, ensuring quality and performance.

The restored blade is lifted and reinstalled in the turbine hub. Our team performs final alignment and balancing tests, verifying control system operation. The turbine then undergoes operational tests to ensure maximum efficiency and safety, validating the solution and extending service life.

The project is validated by component-level structural testing under static and fatigue loads, along with computational analysis based on IEC 61400 standards. Full-scale testing can also be performed upon client request.

The repair is designed and validated to match the original blade’s lifespan, which is typically 20 years.

In addition to the root replacement, a structural inspection of the entire blade can be carried out. This allows for the identification and repair of other issues, such as leading-edge erosion, reducing total repair costs by enabling ground-based work rather than at height.

Yes. Over 250 blades have been repaired and have been operating safely for more than 3 years

Generally, there is a slight increase in blade weight, with no significant change in performance. However, the leading-edge inspection helps restore the blade’s aerodynamic performance to its original state.

The assembly and disassembly process of the blades on the generator takes up to 48 hours. If pre-repaired blades are available, the generator will be offline for only 48 hours. If immediate replacements are not available, downtime may vary depending on logistics and site infrastructure conditions.