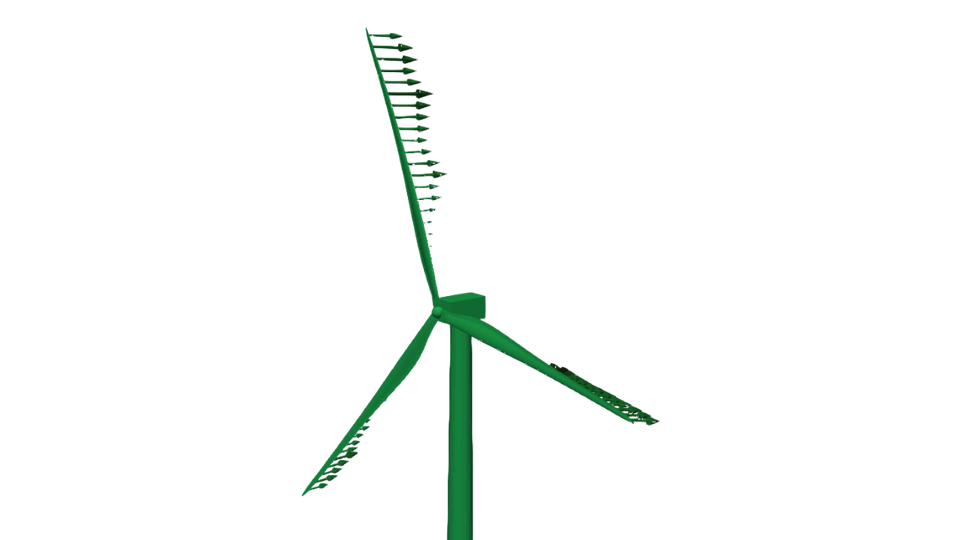

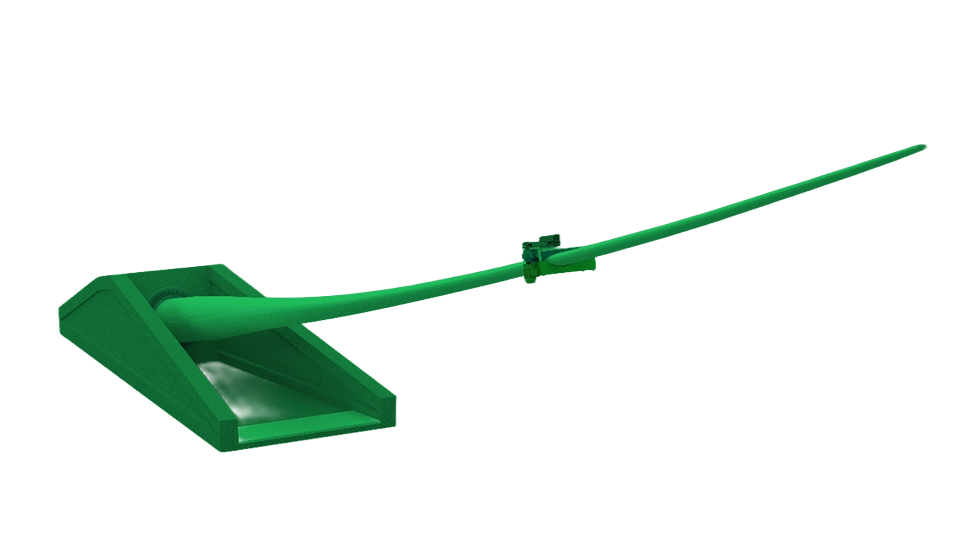

At NewCo, designing blades means aligning science, engineering, and economic feasibility to achieve the highest possible performance for each turbine. We work through all stages — from requirement definition and aerodynamic simulations to field validation — using industry-validated methodologies and state-of-the-art tools. Each project is tailored to the client’s operational conditions and goals, ensuring greater energy production, compliance with international standards, and a lifespan exceeding two decades.

Rated power, rotor diameter, wind conditions, and applicable standards (IEC, DNV).

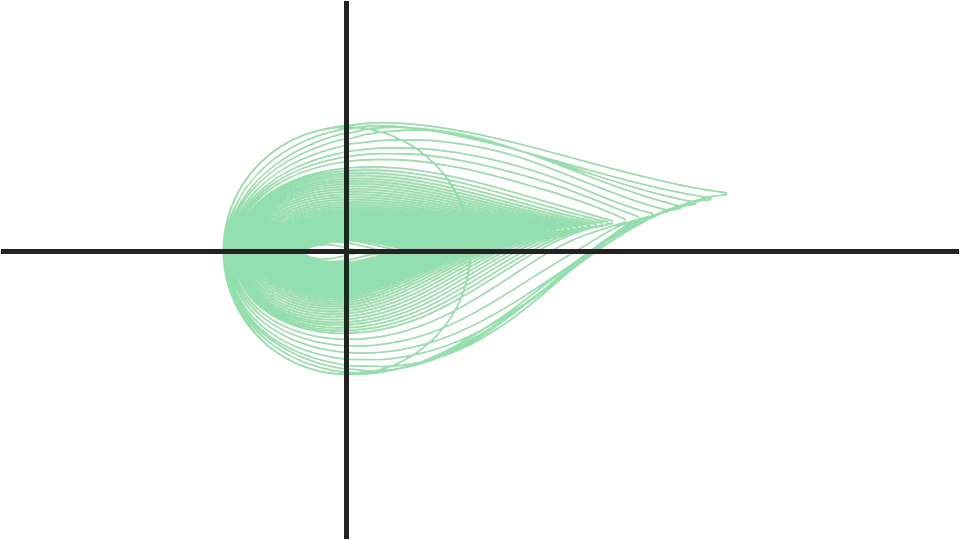

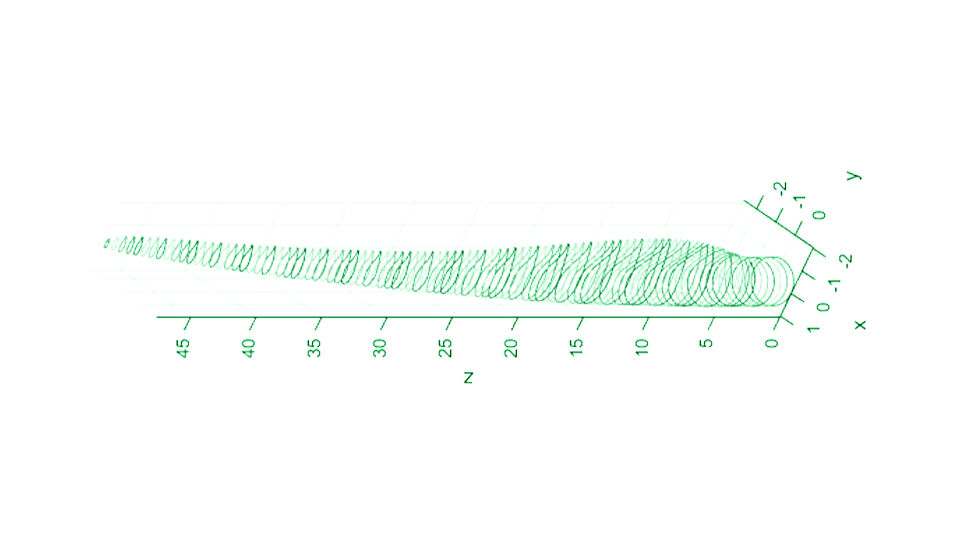

Use of CFD and 2D analyses to select profiles and optimize performance under various conditions.

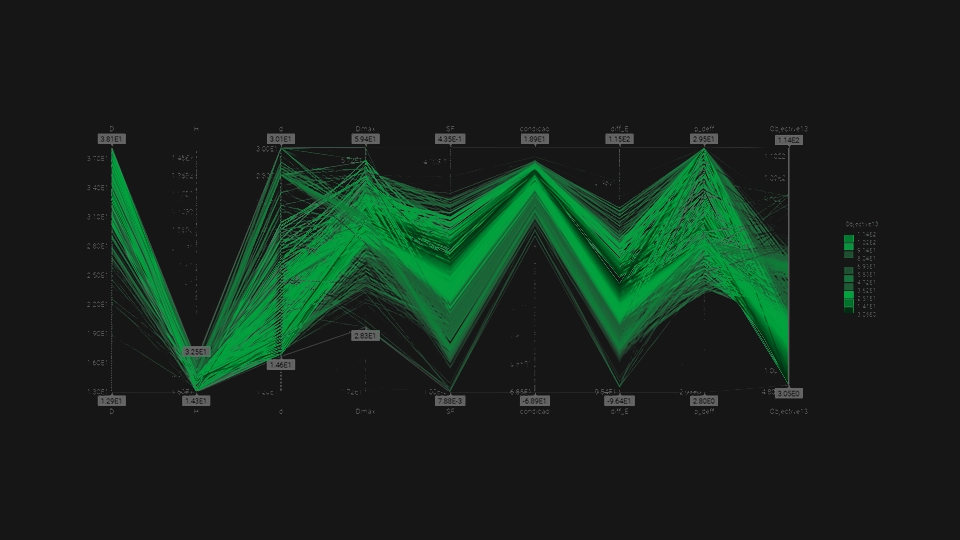

Integration of aerodynamics, structure, and cost with thousands of simulated configurations.

FEA modeling to assess stress, deformation, and fatigue, ensuring reliability.

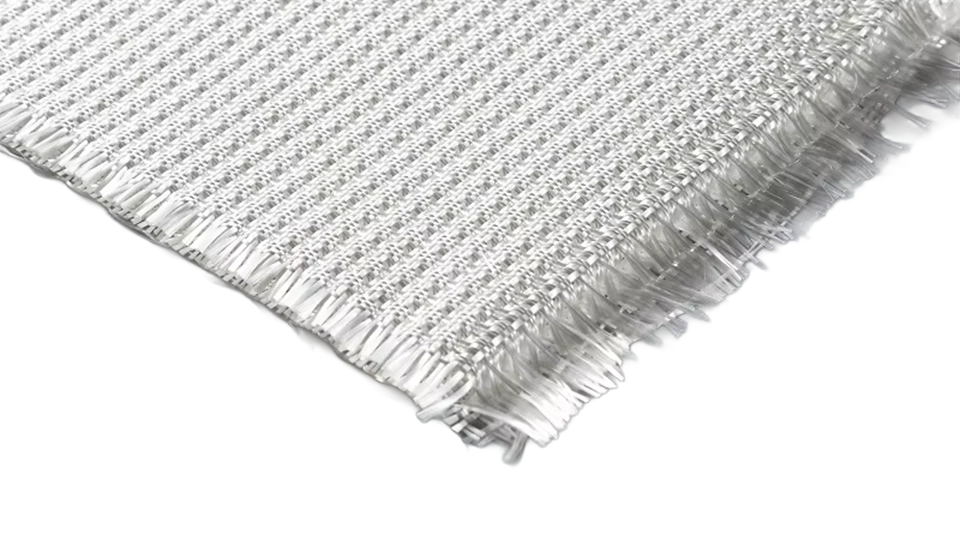

Composites optimized for weight, cost, and long-term durability.

Validation through static and fatigue tests in accordance with IEC 61400-23.

Our projects combine deep knowledge in aerodynamics, structures, and materials to deliver high-impact operational solutions. We integrate all phases — design, testing, and manufacturing — to develop blades that reduce noise, optimize structural loads, and increase AEP. The result: more efficient, reliable, and competitive turbines throughout their entire life cycle.